Written by Ibrahim Y

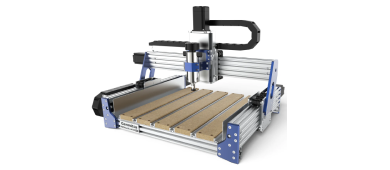

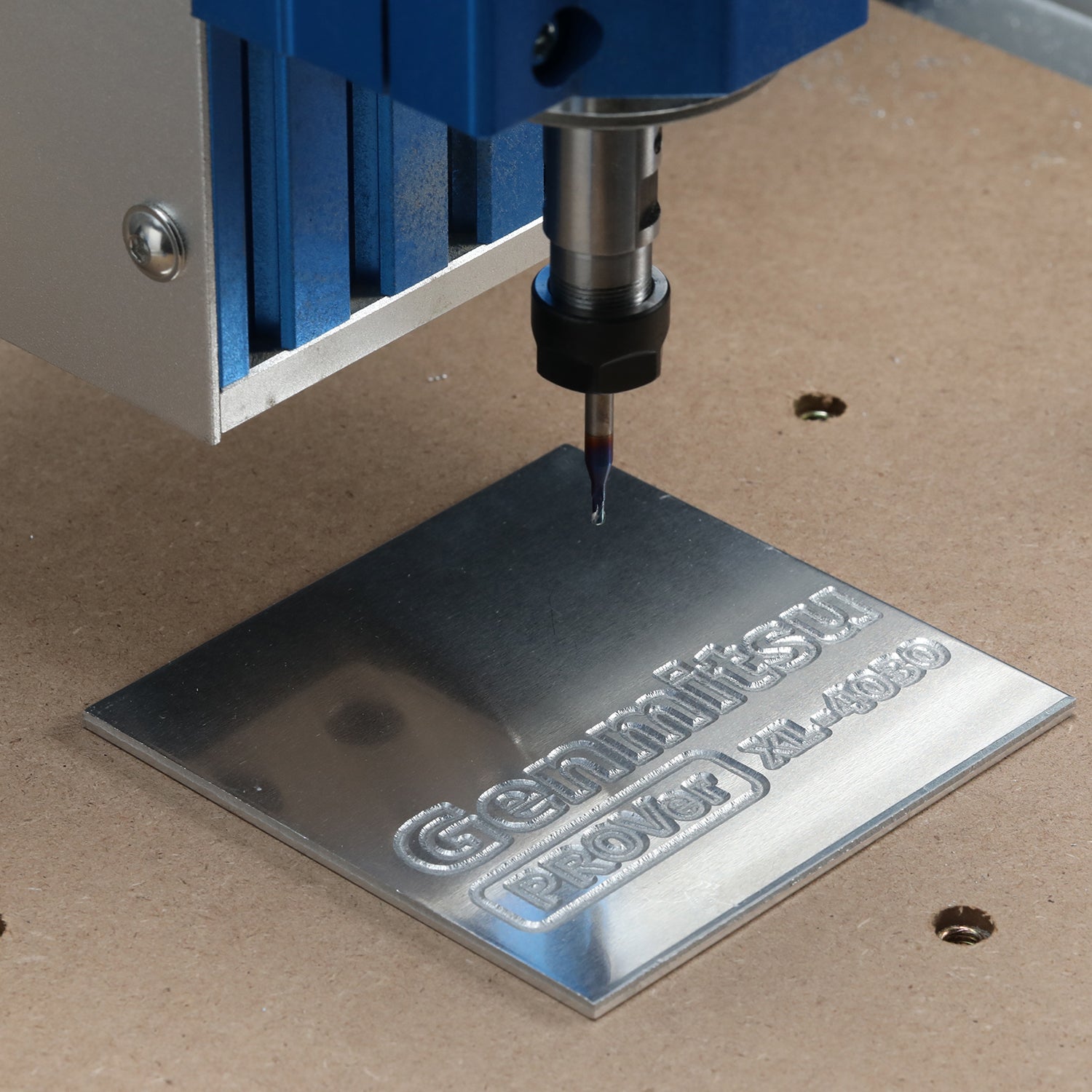

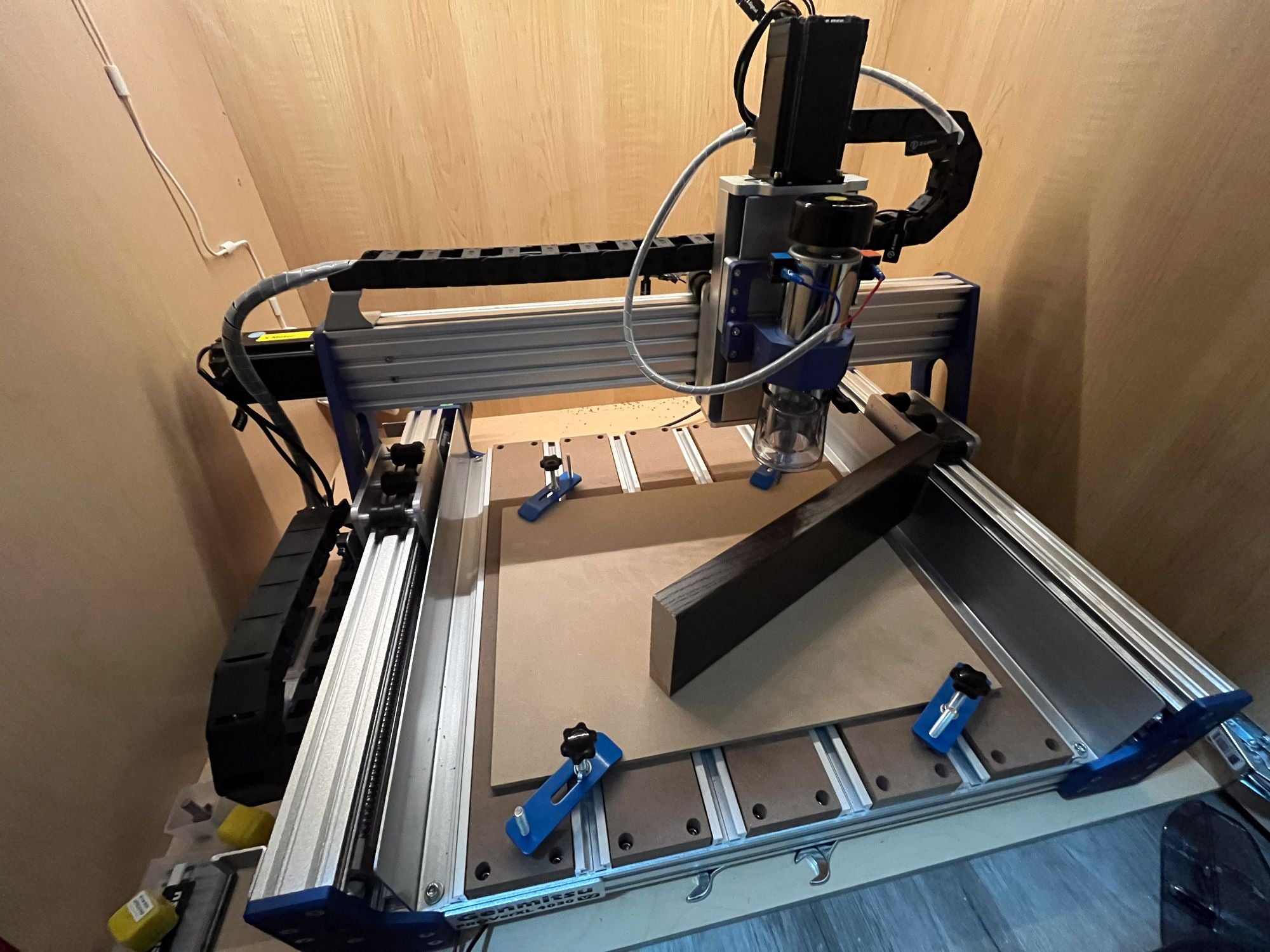

The Genmitsu 4030 V2 CNC may be small in stature, but it’s a giant in performance. Its diminutive size belies a sturdy construction that exudes quality and reliability. The machine’s frame, constructed from high-grade aluminum, provides a stable foundation for precision work, making it clear that this tool means business.

Quality and Precision

Every component of the Genmitsu 4030 V2 CNC speaks to a commitment to quality. The lead screws are precise, the stepper motors are robust, and the controller is user-friendly, ensuring that from setup to execution, your experience is seamless. The attention to detail in design translates to an equally meticulous output, whether you’re carving intricate designs or working on more substantial projects.

Future-Proof Design

Perhaps one of the most compelling features of the Genmitsu 4030 V2 CNC is its potential for expansion. The modular design allows for upgrades and modifications, ensuring that as your skills grow and projects expand, your machine can keep pace. This adaptability makes it a perfect fit for anyone from hobbyists to professionals who may need to scale their operations.

Versatile and User-Friendly

For newcomers, the Genmitsu 4030 V2 CNC is a welcoming introduction to CNC machining. Its straightforward assembly and comprehensive documentation mean you can go from unboxing to creating in no time. For the hobbyist with limited space, it’s a dream come true, fitting comfortably in a small workshop without sacrificing capability. And for professionals, it’s an excellent addition to the arsenal, providing a dedicated machine for smaller, detailed work or as a reliable backup.

Test Run

3D Files:

3D file attached you can open using Blender, Blender is an open source 100% free software, after you open the piece you can scale it as per your need or export it to STL to import into your favorite G-Code toolpath creator.

Download 3D Carve Top Piece.blend

The Processes

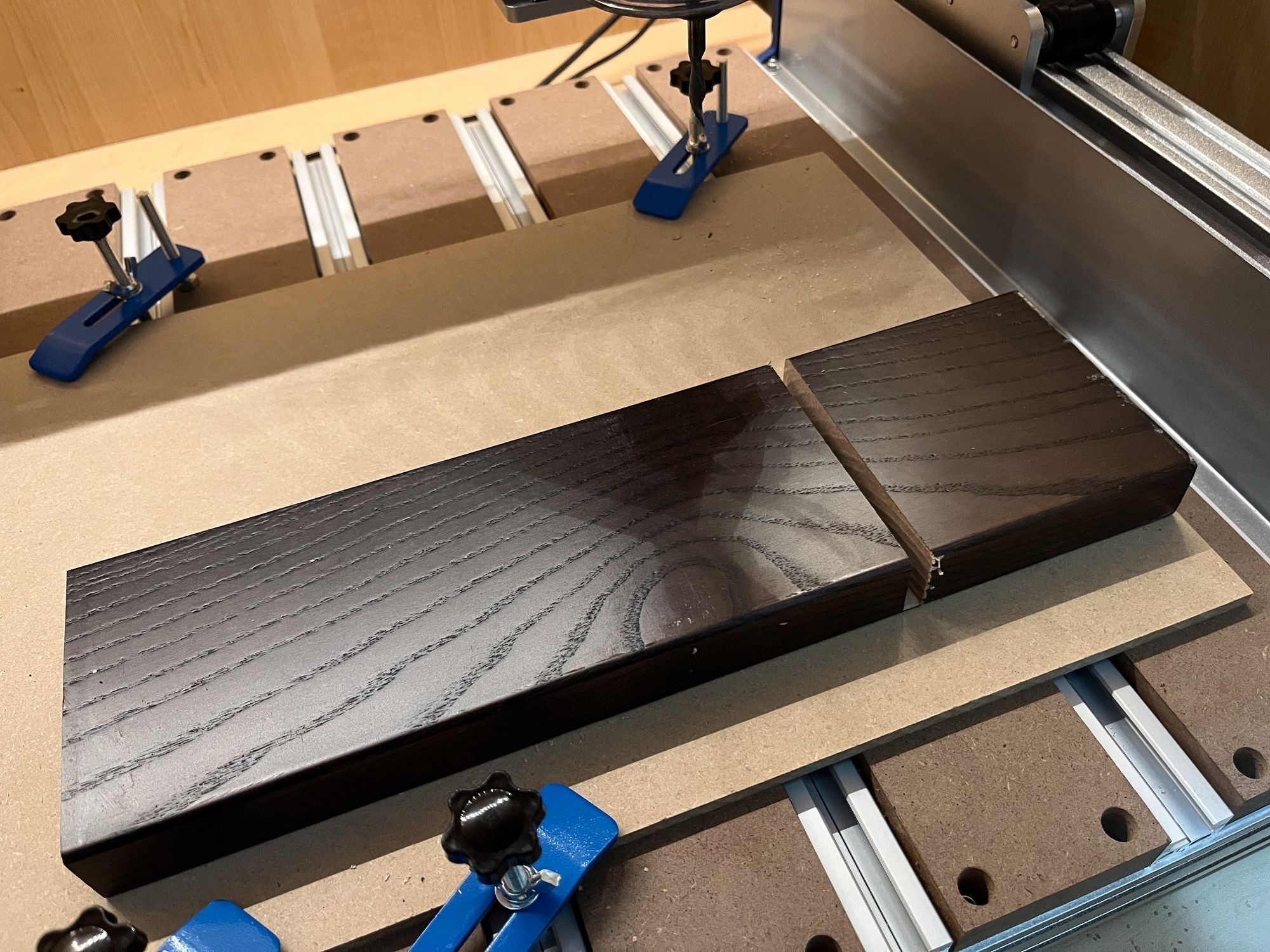

I usually like to design my pieces based on the scrap wood I find. for this piece, I found this tossed piece of wood and tried to design my circular jewelry holder to fit the maximum width I can get from this piece.

Knowing my widest part of the piece around 90mm, I designed the piece to be arounnd 88mm in Diameter. I will challenge my self and produce this entire piece using the Genmitsu 4030 V2 CNC only, nothing else. no band saw no planers no nothing!

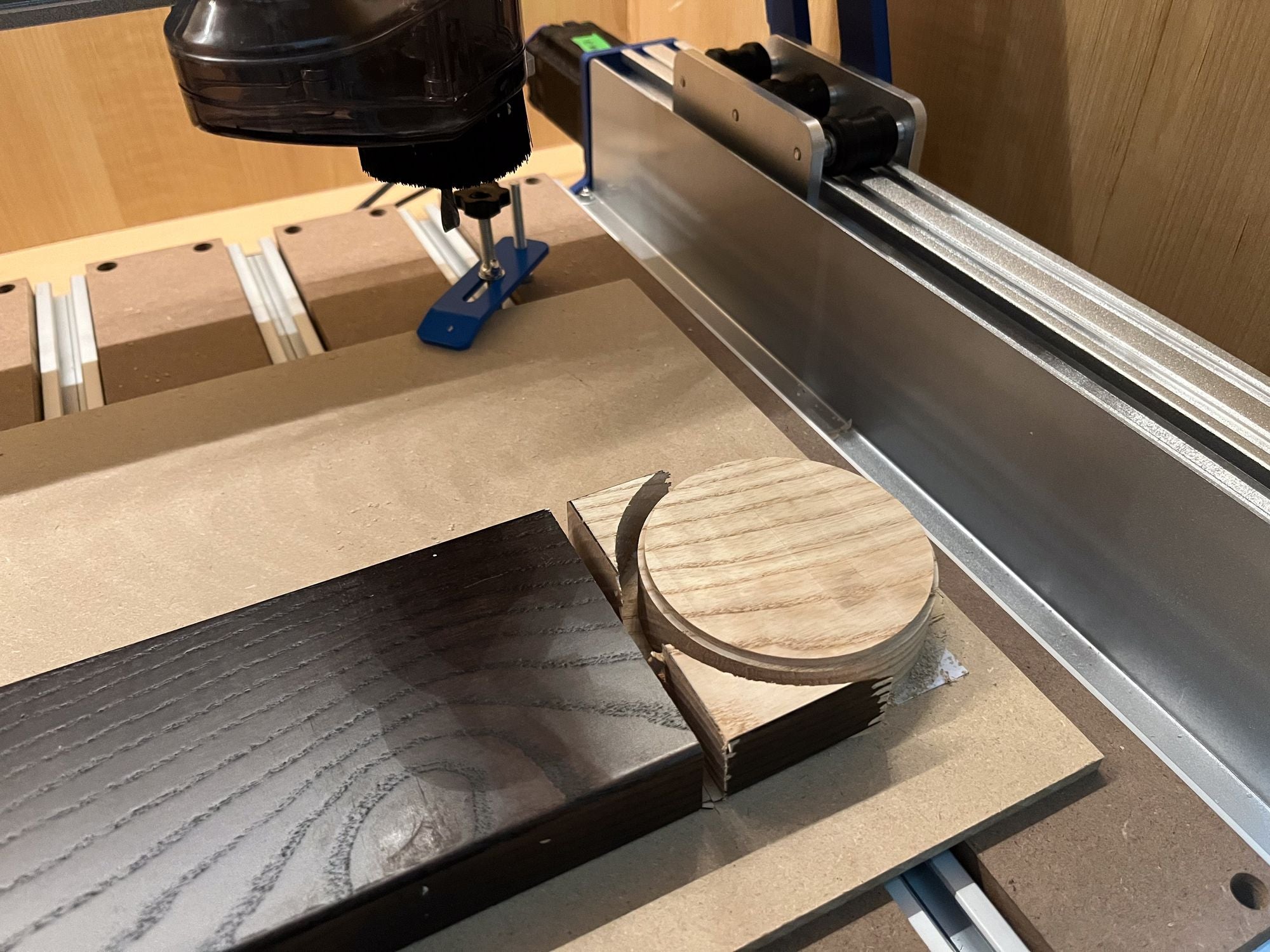

To start the challenge I needed to separate the piece from the main body using a down spiral bit, I did this by running a 1.5mm passes to get the piece separated.

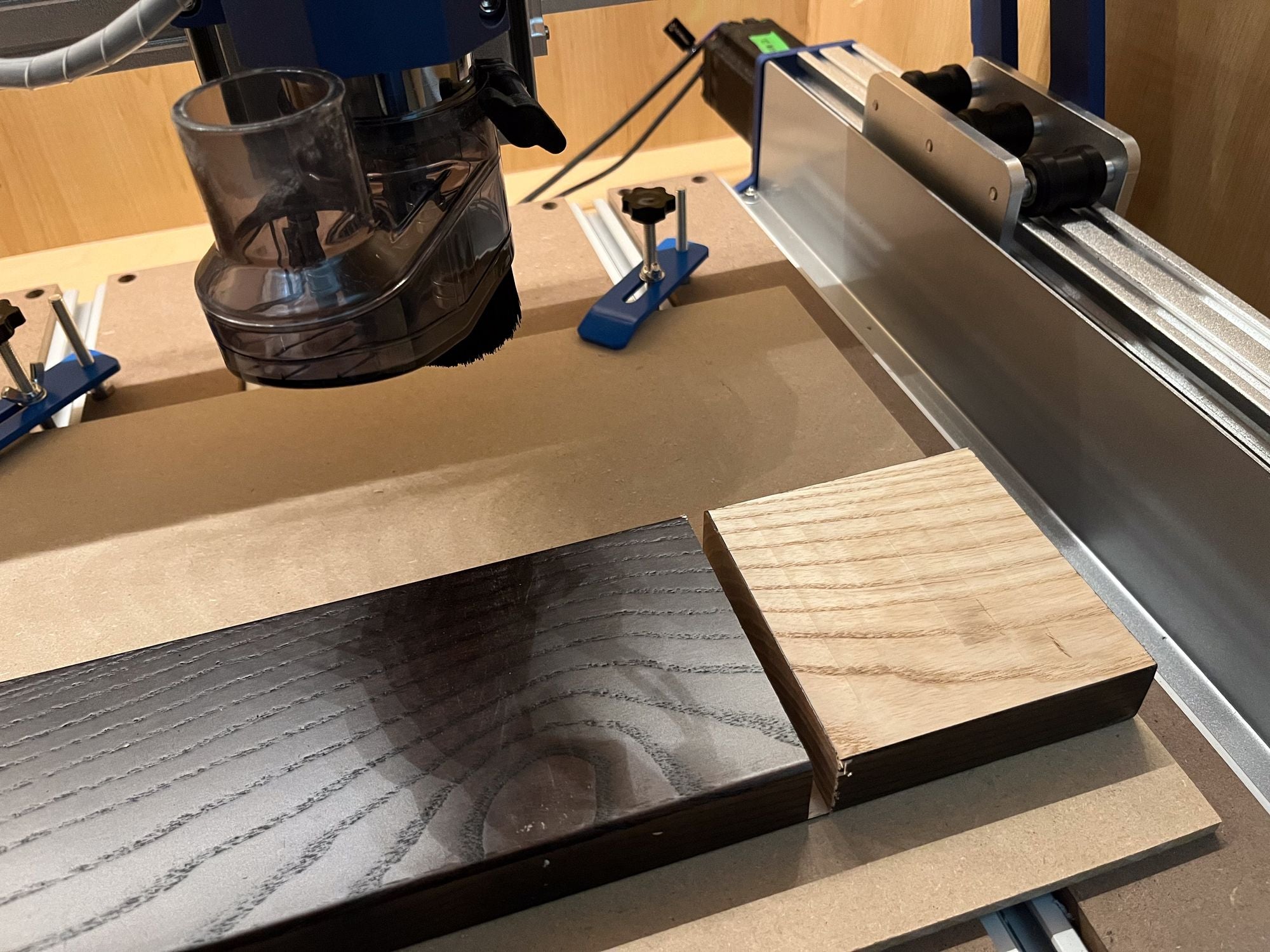

After having the main body ready for the work, I started by making sure I got a flat surface, using the surfacing bit, the surfacing bit can’t plunge down, so I had to bring it from the side, took little longer that I expected, but it was important to have a leveled surface since I dont know the condition of the wood.

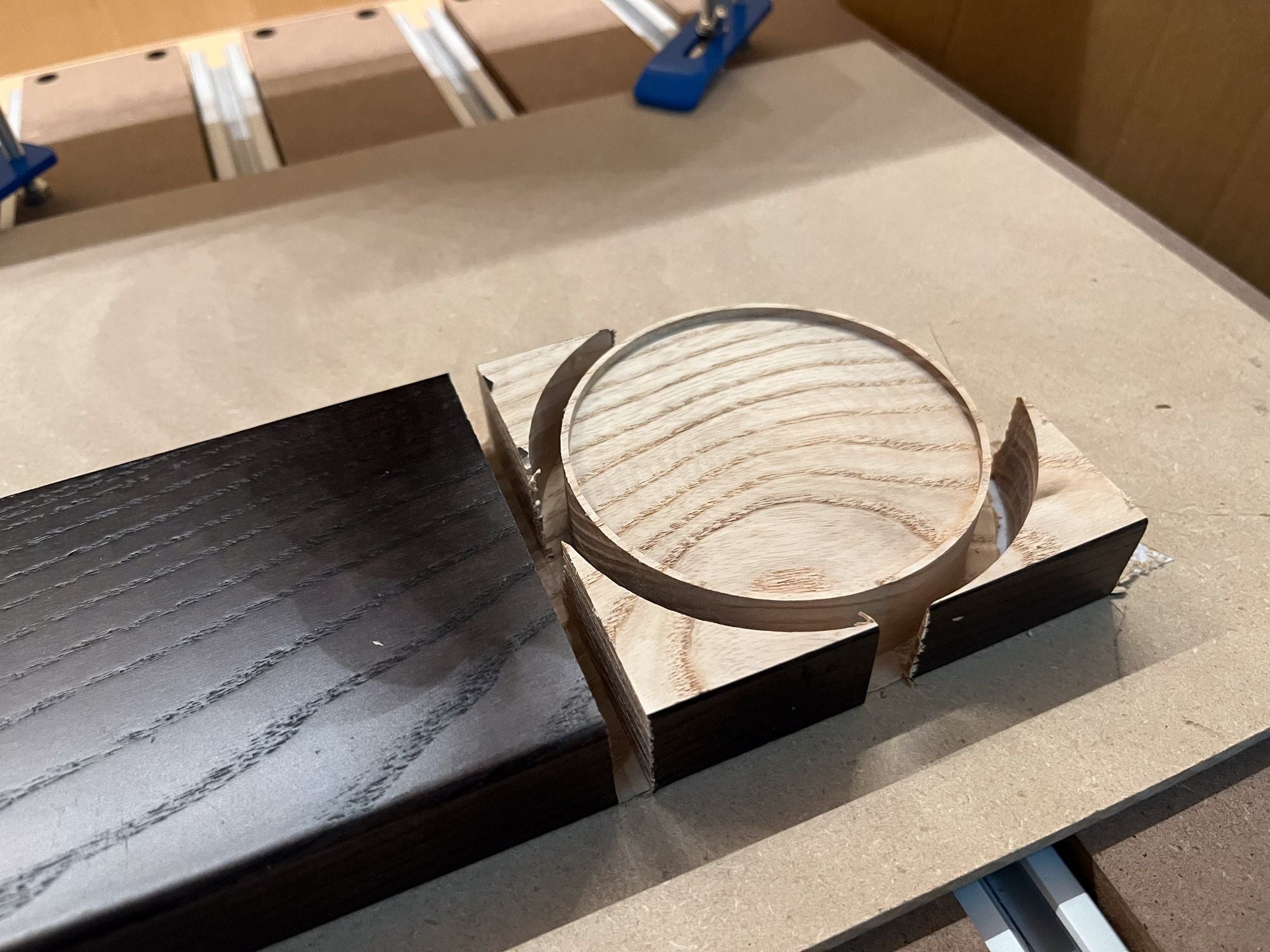

After having the main body separated and flattened, its time to start the fun part, actually creating the piece. I started by milling a perfect circle of 88mm diameter, all the way down. I also had the change to create the upper ring at 84mm with only 4mm depth.

To pocket this piece properly, I had to split the pocket operation into two, operation 1 take the most our of the material, operation two to create a rounded bevel on the edge, to get this smooth round transition between the edge of the piece and the bottom of the piece. for the rounded edges of the interior walls I used Cove Rounded Bit 12.7mm (half inch).

Finally its an optional step, but you can go little fancy and run a bevel on all the top edges, as long as the bottom edge (if you flip the piece for further beveling) for the beveling 45 degree I used a bit from the same collection I found on amazon, V Grove Bit.

for the Top piece, I started by cutting the main rounded shape and pocketing the inside, this image shows the Bottom of the Top piece.

After creating the pocket, I had to create the same profile on a piece of MDF to be able to glue the piece to the board. this is important so you can run the top side of the top piece. starting by removing the big chunks with a 2mm bit, then 0.8mm bit to clean up the final pass, this was the most time consuming part of the whole build, those two programs took around 1.5 hours to run, maybe I over did my step overs, and I could have probably run it a little faster next time.

Now the piece is pretty much ready, little bit of sanding and oil for the piece, and we got a final product from a printer size cnc on my desk (under my desk). super fun! will leave you with the final product images below:

List of G-Code for further studies

This is the exact G-Code I run on my CNC, I would recommend to export your own depends on your wooden piece that you plan to run. but use those as a reference, you can optimized them probably to reduce the steps needed and combine some of them in 1 single file. but I was designing and running at the same time, and I ended with lots of pieces.