Posted by SainSmart on

written by Dennis Heinze, excerpt from hardwarepoint.

3018 PRO DIY Laser Upgrade

There has already been talking in several chapters about the 3018 PRO DIY, which we have upgraded with a laser.

This was our first point of contact with lasers and since then we have implemented a number of projects. The learning curve is steep, and you get good results quickly, unlike what may be the case with milling.

Air Assist

The LC-40 has air assist via a 40mm fan and air baffle which ensures smoke is blown out to the rear.

Comparison

The increase in effectiveness should also be mentioned...

Ultimately, no clear purchase recommendation can be made between the 3018 PRO DIY Laser with Air Assist and the LC-40...

Read more on Hardwarepoint

Tags:

Product Review

In Same Category

- Elevate Your Craft with Genmitsu’s Vibration-Free Vise Clamp

- Exploring the Genmitsu Kiosk 10W Laser Engraver: A Game-Changer for Compact Engraving

- Review The Ultimate Gravel Cleaner for Effortless Aquarium Care

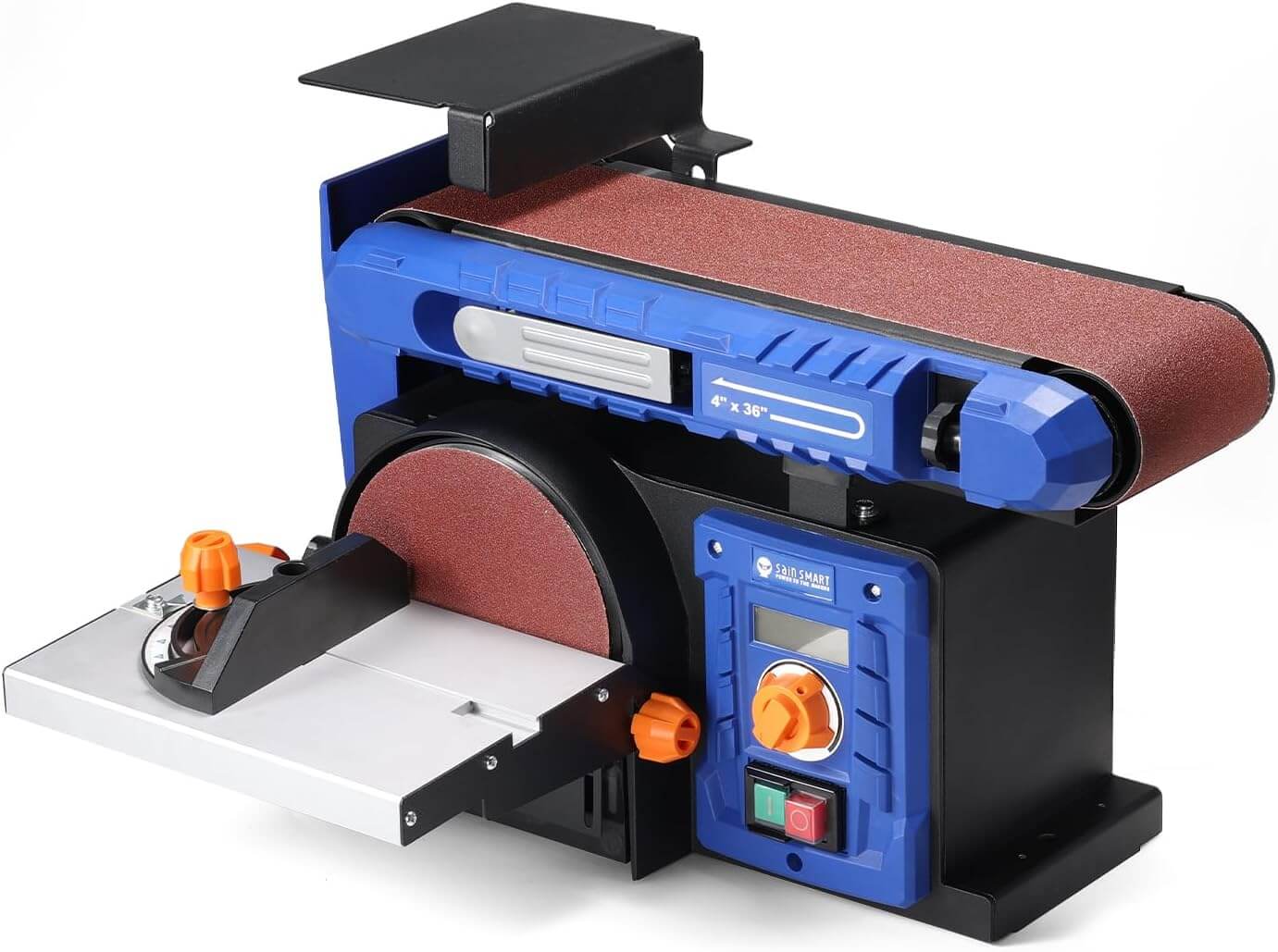

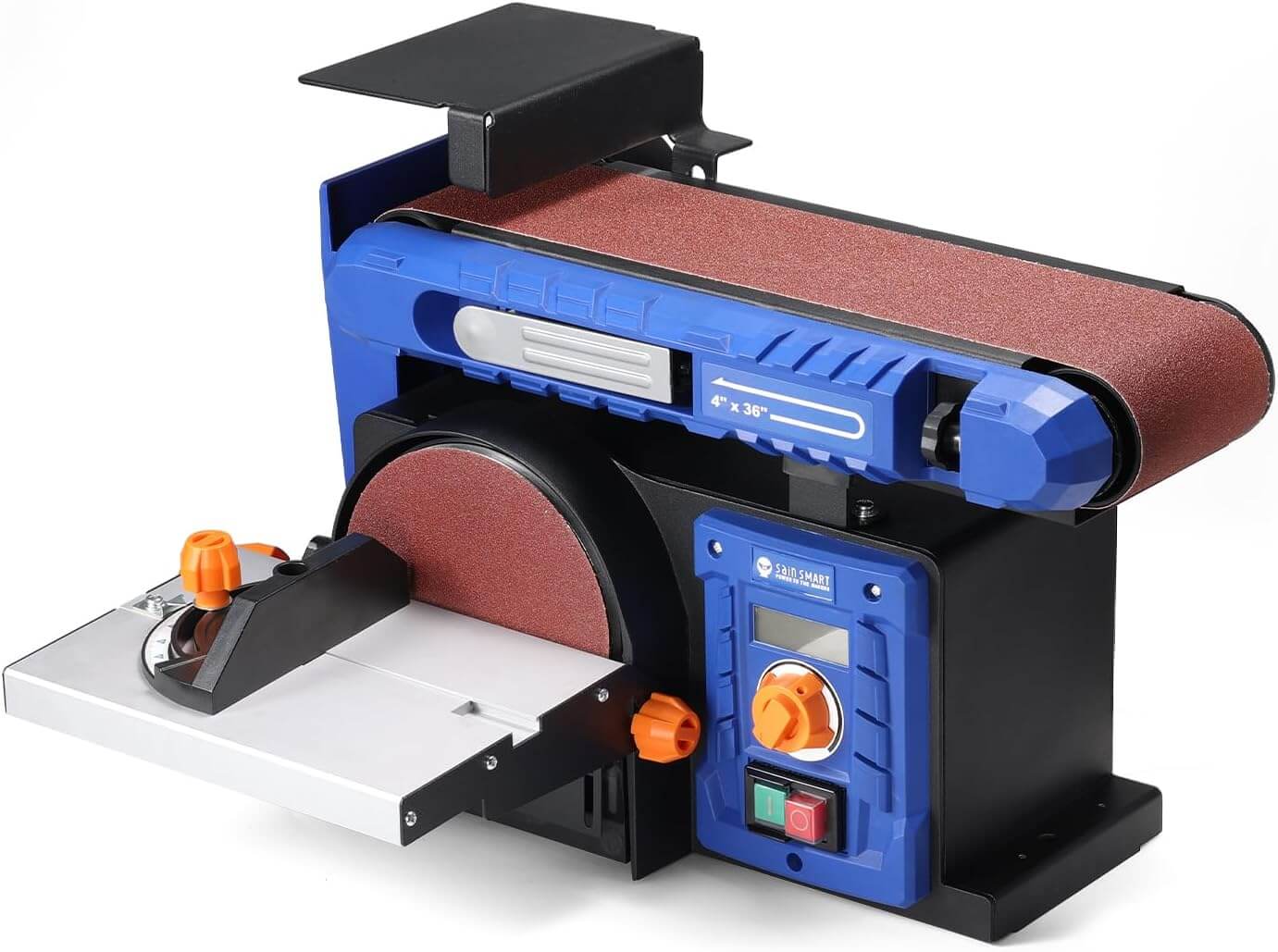

- Review: Functional Disc/Belt Sander That Excels with Variable Speed Control

- Join Us at the 2025 National Hardware Show – Free Tickets, Exclusive Offers, and Cubiko Live Demo!

Related by Tags

- Elevate Your Craft with Genmitsu’s Vibration-Free Vise Clamp

- Exploring the Genmitsu Kiosk 10W Laser Engraver: A Game-Changer for Compact Engraving

- Review The Ultimate Gravel Cleaner for Effortless Aquarium Care

- Review: Functional Disc/Belt Sander That Excels with Variable Speed Control

- Discovering the Genmitsu L8 Laser Engraver: A Game-Changer for Hobbyists

- Review Adjustable Belt Disc Sander: Perfect for Hobbyists

- Review SainSmart PROVer XL Upgrades 4030 V2.1 [Part 2]

- Review SainSmart PROVer XL Upgrades 4030 V2.1 [Part 1]

- Using the 4040 RENO CNC For Inventics Projects

- Review of the SainSmart Genmitsu 3030-PROVer MAX

- 710W CNC Spindle Motor Review

- PROVerXL 4030 V2 Review Part 2 - Projects & Results

- PROVerXL 4030 V2 Review Part 1 - Assembly and Calibration

- Discover SainSmart Filament: Your Choice for Reliable 3D Printing

Recent Articles

-

-

-

-

-

-

Unlock Your Maker Potential: Crafting with the Genmitsu Cubiko CNC

Unlock Your Maker Potential: Crafting with the Genmitsu Cubiko CNCFebruary 11, 2025

1 comment

Estoy interesado en montar en mi CNC un equipo de corte por laser que sean compatible