Written by Duane L

First of all, props for the environmentally friendly packaging: the sander was secured by formed cardboard and only a few plastic bags for the sander and parts.

Performance on Various Materials

After several weeks of use on soft and hard woods, I'm impressed by how well the sander works on both.

Speed Control

The ability to change the speed of the belt and disc allows you to take your time when working on intricate shapes, as well as avoid discoloring hard woods with high speeds. Lower speeds also help when de-burring aluminum and soft metals.

User-Friendly Controls

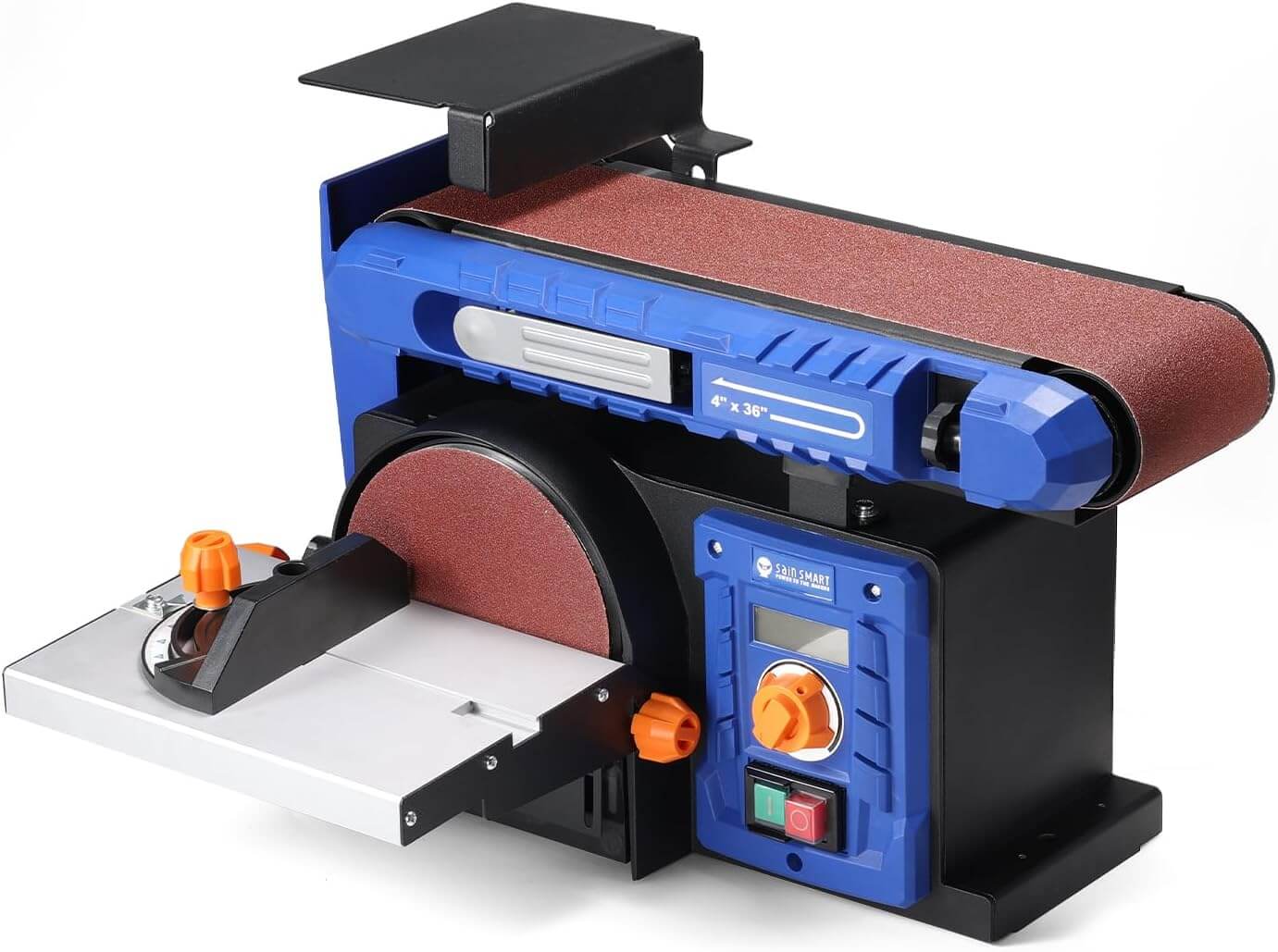

The controls are very easy to use. Turning a dial sets the speed, and a large LCD screen displays the current speed. Because a dial is used to set speed, you can resume work at the same speed even if you unplug the sander (as long as you don't accidentally move the dial).

- Safety Features: The start and stop buttons are large enough to use with gloved hands. The slightly recessed green start button and slightly proud red stop button make it difficult to accidentally start the sander, but very easy to stop if needed.

- Power Safety: When unplugged from main power, the start button will not engage when you plug it in. You must plug in the sander for the start button to work. Very well thought out.

Design and Usability

Working Surfaces

The working surfaces for both the belt and the disc were well planned. The stop for the belt has enough room to rest your hand or material when sanding, without blocking your view or access to the belt.

Generous Work Table: The work table and angle guide for the disc table are very generous. There is little play in the angle guide, making it easy to slide in either direction for safe and comfortable access to the disc.

Dust Collection

Having a dust collection port significantly cuts down on airborne particles and makes clean-up much easier.

Instructions and Assembly

The instructions were clear, and diagrams were helpful. My only complaint is that the instructions and diagrams are separated by several pages in the documentation, making reference a little difficult.

Assembly is straightforward: 2 hex/Allen screws for the belt stop are tightened with the supplied hex key. The work table for the disc requires 2 hand screws and 3 10mm nuts. I found it easiest to assemble by tightening the 10 mm nuts snugly (but not completely) to level and square the work table and angle guide.

Changing either the belt or the disc only takes about 5 minutes and requires the supplied Allen key and a Phillips-head screwdriver for the belt and only a screwdriver for the disc. (Much easier than my previous sander.)

Conclusion

I'm a hobbyist and maker. This sander provides the control, safety, and versatility I need to work on projects using plastic, wood, and soft metals. I've already mounted it on a stand in my shop and know it will be able to handle anything I can throw at it.