Written by Dennis Heinze

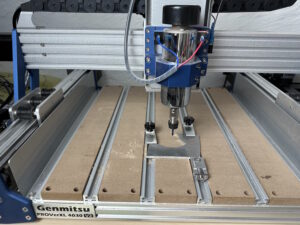

As is almost customary, we bring you a suitable upgrade path for the recently presented desktop CNC milling machine, the SainSmart 4030 PROVer XL V2. We are building a version 2.1.

This time in the form of a new spindle, corresponding control, accessories, and new tools. Many thanks to SainSmart for providing the products for this article. On the last page, you'll find a link where you can also save 10% in the SainSmart Shop and leave us a small commission.

710W Spindle Upgrade

The included spindle of the 4030 PROVer XL V2 is suitable for initial milling attempts. However, for aluminum machining, a larger motor is required. The 710W kit is a router without a housing. Unboxing: The motor comes securely packaged with instructions, spare carbon brushes, and an extension cable.

Technical Data

| Input Voltage | 220-240 V AC |

| Power | 710 W |

| Speed | 6 levels, 7000 – 30000 RPM |

Application

The 710-watt motor fits into the holder of the 4030 and is powered directly. A handwheel allows for speed adjustment. The spindle uses an ER11 clamping system, compatible with many bits.

Brush Replacement

Four spare brushes are included in the package. The replacement is simple and quick.

We will show how the motor performs in the milling tests at the end of the article.

Clamping Brackets

Securing the workpiece is an important issue in CNC milling. Many use masking tape and superglue, which works well for flat wood projects. However, for metalworking, proper clamps should be used.

The included clamps are a start but often stand too high above the workpiece. In a previous article, we presented the silver, tool-free clamping brackets for T-slots:

Now SainSmart has a flatter version with only 15 mm height, which requires an Allen key. These clamps allow the material to be placed higher than the clamps, reducing the risk of hitting the clamp while milling.

The clamp is anchored in the T-slot, and the side screw tightens the material. The clamping part is angled downward, creating a movement towards the milling bed. Often, it helps to press the workpiece down onto the milling board after lightly tightening with a rubber mallet.

Overall, this is a good addition. Having different clamping systems readily available is often helpful, as each project is different.

iMatic Box 02 Relay

The relay box was already mentioned with the spindle upgrade. Regardless of which motor is used, most have their own power supply. For VFD-controlled spindles, the original signal can be adapted to control the speed.

The iMatic Box allows for the switching on and off of two 230V devices, such as the spindle and the dust extraction, without having to disconnect or solder cables. Just connect and you're done.

Contents

The box includes five adapter cables, four mounting screws, a power cable, and instructions.

Application

The adapter cables are for signal control and vary depending on the SainSmart CNC model. The relay box is connected to the laser port of the CNC. The cables are labeled with letters and bring a PWM signal to the relay box.

| Cable | CNC Model |

| A | 3018 PRO, 3018 PROVer V2, 3020 PRO MAX V2 |

| B | PROVer XL 4030 V1 |

| C | 3018 PRO, 3020 PRO MAX |

| D | PROVer XL 4030 V2 |

| E | 3018 PROVer |

To use the relay box, the devices must be connected to a 230V socket. The "Relay Enable" switch must be pressed for the devices to be activated.

The relay box is rated for 10 A and should not draw more than 2000 W. Technical data are:

| Power Supply | 12 V DC |

| PWM Voltage | 5 V DC |

| AC Input | 220 V AC, 50 Hz |

| AC Max Current | 10 A |

For mounting, I attached the box with Velcro to the CNC controller, next to the wireless module. This way, no PC is needed to send the machine code.

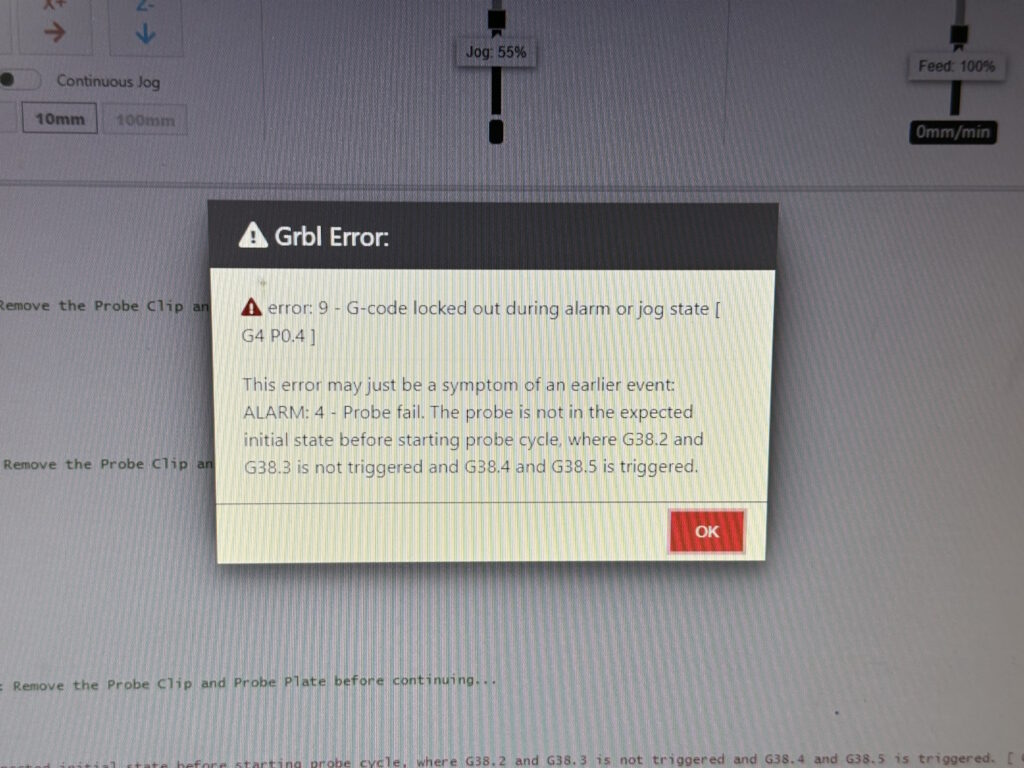

Using a standard grounded power cable simplifies the Z-probe, as only one cable is needed. During the test milling, it became apparent that the crocodile clip on the tool can now be omitted.

The voltage is applied to the base plate, and as soon as the tool touches the base plate, the circuit is closed. However, this only works with insulated Z-probes.

Milling Tests

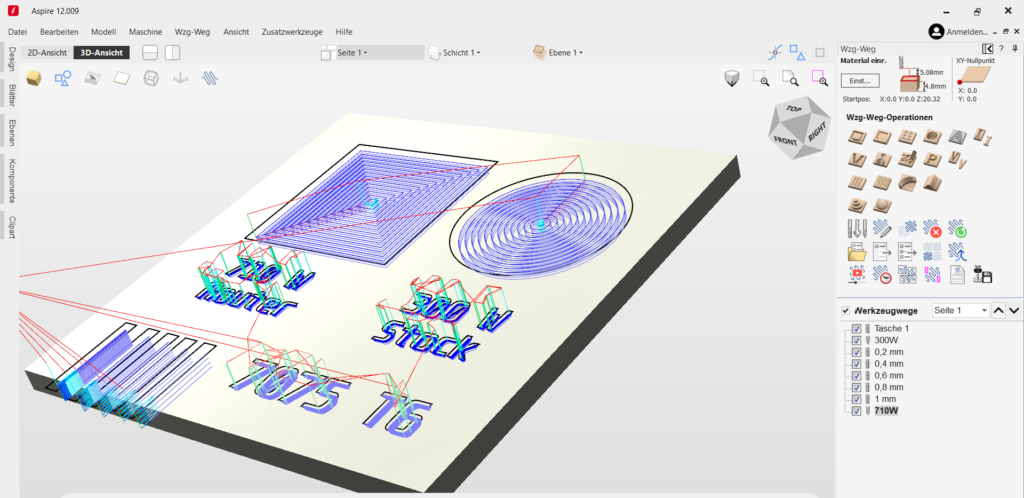

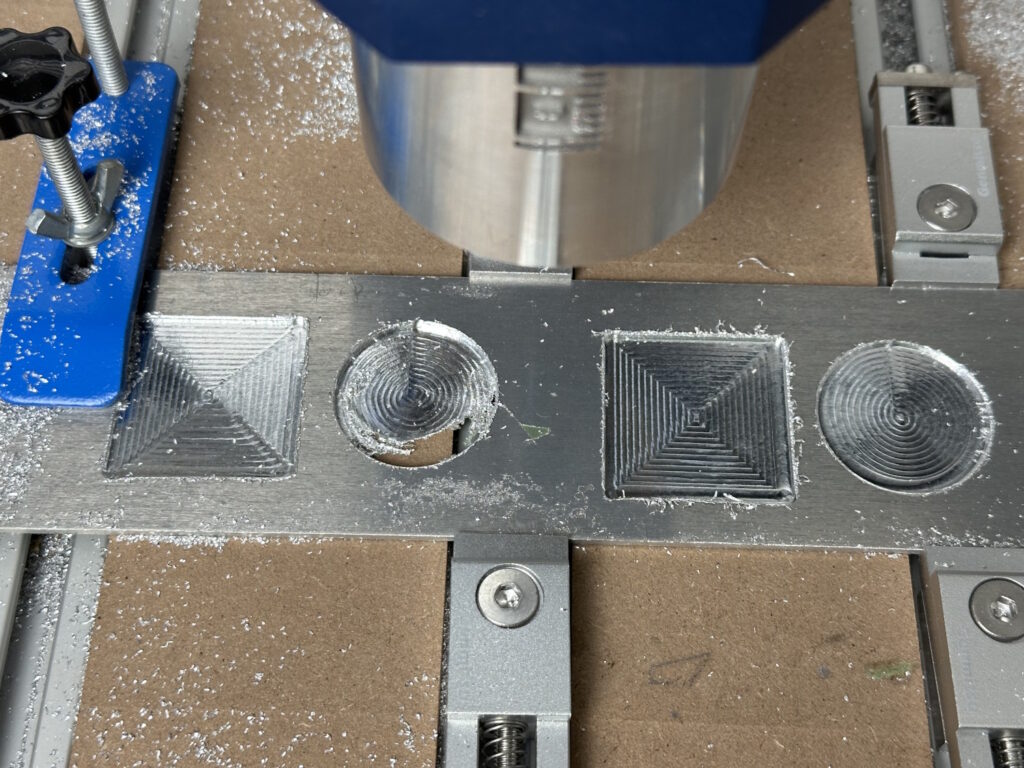

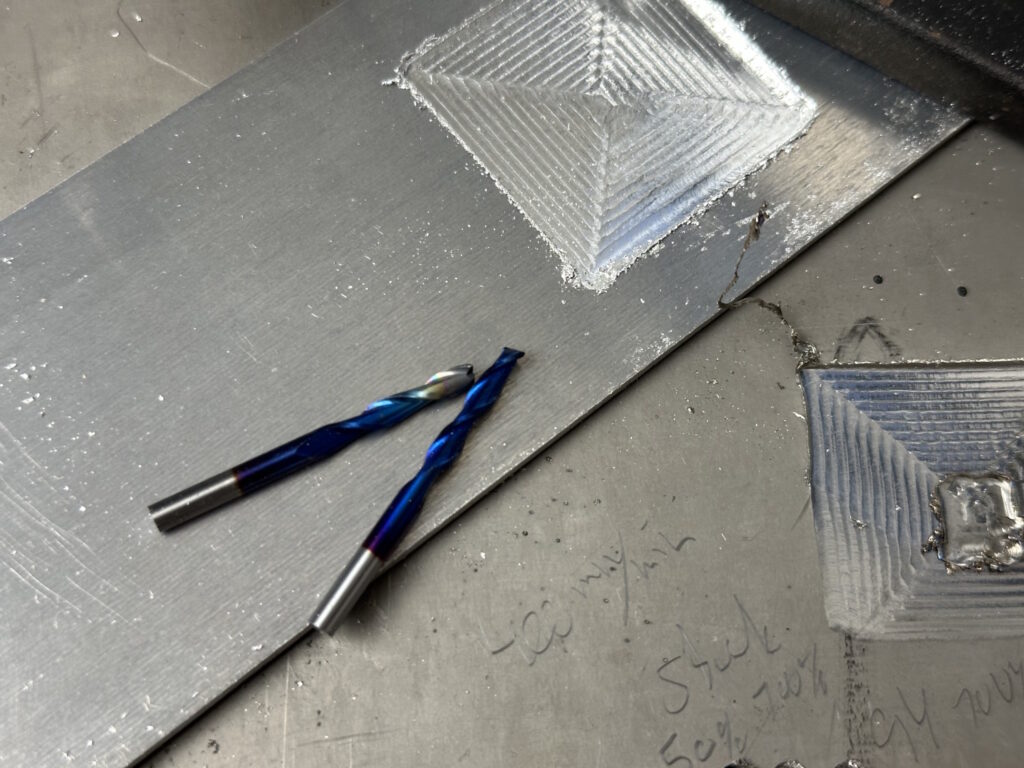

After examining the individual components of the upgrade to the PROVer XL 4030 V2.1, it's time for milling. Using Vectric Aspire, we created several test files. (More information about Aspire) A new cutter performs several groove milling operations at 400 mm/min and 11,000 rpm, but with different depths of cut.

The depths of cut were: 0.2 mm, 0.4 mm, 0.6 mm, and 0.8 mm. At higher depths of cut, the surface quality deteriorated. The milling strategy was conventional milling.

We examine the surface finish and noise during milling, as well as the results in 7075 T6 aluminum, titanium, and ST37 steel.

The 710 W spindle produces less vibration and noise than the standard spindle. However, it can become louder at higher speeds.

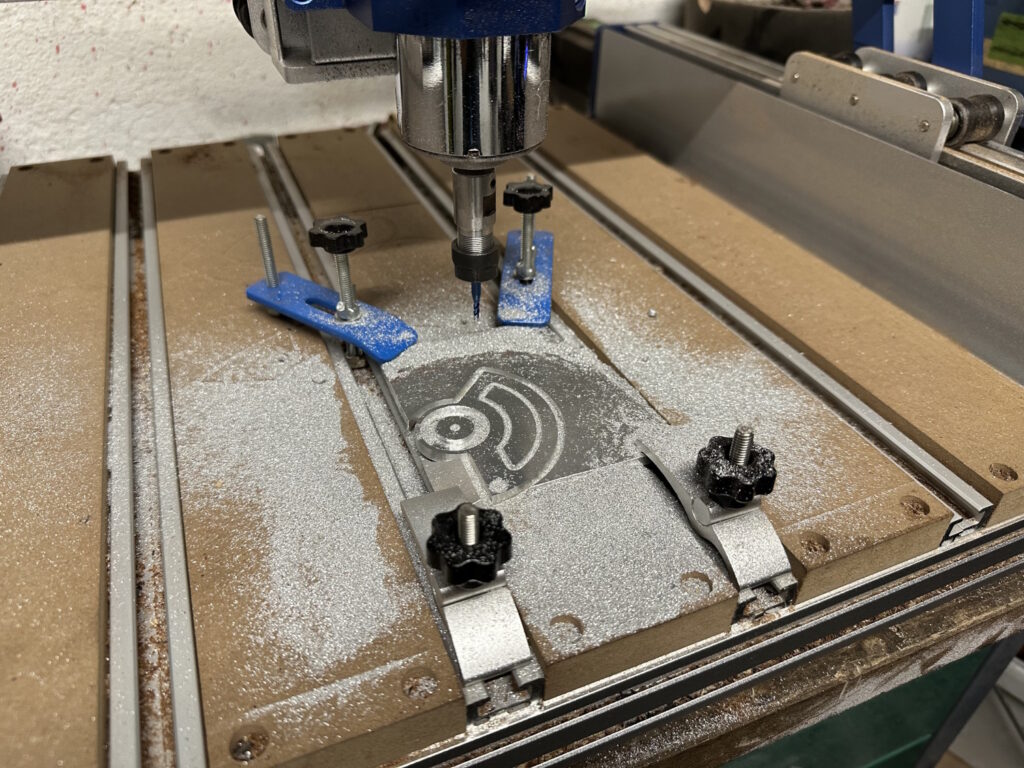

7075 T6 Aluminum

The test showed that the 710 W spindle provides better surface quality at a depth of cut of 0.2 mm compared to the standard version. At 0.4 mm, the surface was rougher, and at 0.6 mm, there were significant deviations.

| Depth of Cut | Aluminum 7075 T6 | Steel ST37 | Titanium |

| 0.2 mm Standard Motor | 3.35 mm | V=25% 3.55 mm | 3.2 mm |

| 0.2 mm 710 W Motor | 3.2 mm | V=25% 3.3 mm | 3.2 mm |

| 0.4 mm 710 W Motor | 3.25 mm | not tested | not tested |

The measurements of the rectangles and circles show that the 710 W spindle achieves better results. The values are listed in the following table:

| Aluminum Circle | Aluminum Rectangle | Titanium Circle | Titanium Rectangle | |

| Standard Motor | 32.8 mm | 36 mm | 32 mm | 35.91 mm |

| 710 W Motor | 33.9 mm | 37 mm | 33.6 mm | 37 mm |

The pocket milling shows irregularities in the milling lines, but the results with the 710 W spindle are significantly better.

ST37 Steel

The standard spindle can process steel, even if the cutting data are not optimal. The results are acceptable, albeit with deviations.

Titanium

The titanium tests were surprisingly successful, even though the standard spindle is pushed to its limits. However, the 710 W spindle delivers significantly better results.

The results show that the 710 W spindle is a successful upgrade, especially in combination with the relay box. Higher cutting data are also possible in wood, although the surface quality is not as pronounced as in the metal tests.

It remains to be seen what a VFD spindle can achieve—perhaps in the next upgrade.

For more details on these upgrades, including deeper analysis and test results, please check out the second part of the article: SainSmart PROVer XL Upgrades 4030 V2.1[Part 2].