Written by David L

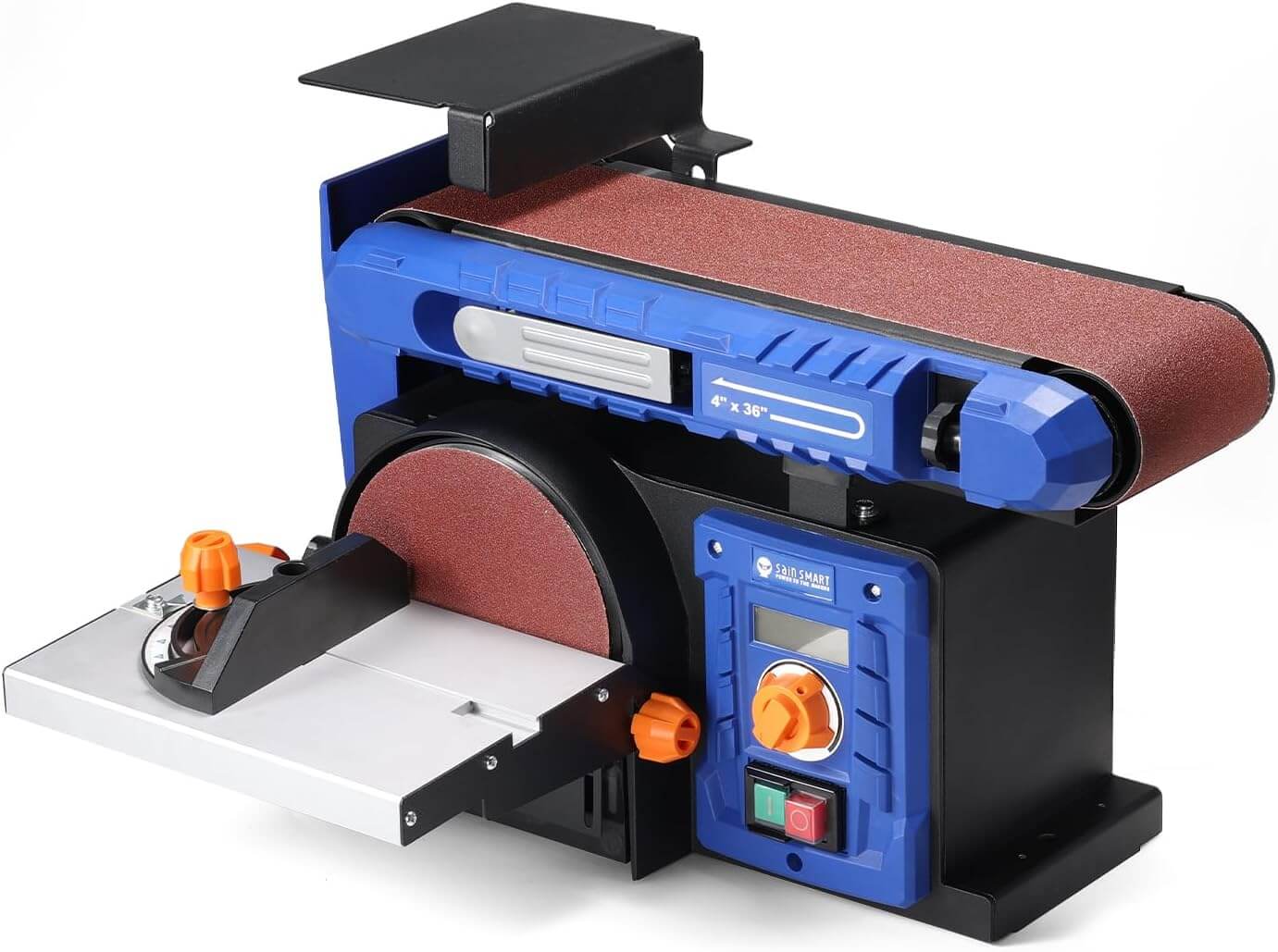

I received this new disc/belt sander 3 weeks ago and have been using it for several holiday-related projects since then. I'd say I haven't fully put it through its paces yet, but do have a sense of what I like about it and what might be improved. First of all, I like the variable speed control on the unit, as I'm often switching between sanding for wood, plastic and soft metals (mainly brass and bronze). Of course, everything works well as expected. The quick-change for the belt and disc are also quite reliable and convenient.

Project Examples and Material Usage Experience

During this time, I used this sander for many projects, such as smoothing the rough edges of wooden signs or sanding brass parts for a homemade lamp. The variable speed control is really a lifesaver, especially when dealing with different materials. For wood, I generally use medium speed; but for plastic or metal, I lower the speed to avoid overheating or melting the material.

I also found that the belt sander is particularly suitable for handling curved edges. Recently, I made a set of rounded wooden coasters, and the belt sander quickly helped me sand the curves to be very smooth. The disc sander is better at handling straight edges. I used it to trim the sides of a wooden box, and the effect was perfect.

Assembly and Worktable Adjustment

Setting the unit up out of the box was for the most part an easy and uncomplicated procedure. The one "gotcha" is how finicky it is to adjust the worktable. There are a couple of locknuts underneath that have to be tightened, which involves attempting to hold the platform in position, keeping the entire unit tilted on its side and stable, and also putting a wrench onto those locknuts to tighten them. It's do-able, but really not convenient. And when moving the worktable over to the belt sander (you can swap out the black metal guard with the worktable and tilt the belt up into a vertical position - which is a nice feature), you have to deal with this finicky adjustment twice: once to get it properly positioned against the vertical belt and once again when its moved it back to the disc. I do wish there was an easier procedure for mounting/adjusting the workstable, though it's not something one does every time.

Tips for Worktable Adjustment

Speaking of worktable adjustment, I found that using a small mirror or mobile phone camera can help me see the locknuts below, so I don't have to turn the whole machine over all the time. Although it's a bit like a "hack," it does save a lot of trouble. I also bought a magnetic parts tray to put the locknuts and wrench in, so I can easily access them when adjusting.

Summary and Recommendation

Overall, I am very satisfied with this sander. It has become an indispensable tool in my workshop, and I can imagine using it for more projects in the future. If you are looking for a compact and versatile sander, I highly recommend trying this one.