Written by Chris

Alright makers, let's dive into the heart of your Genmitsu 4040 CNC! Both the 4040 Reno and 4040 PRO are fantastic machines, but the key difference lies in how they move the cutting tool: belts versus lead screws. Understanding these two drive systems will help you get the most out of your new desktop CNC machine.

4040 Reno: The Speedy Budget Ninja

At the core of the 4040 Reno is an easy to maintain belt drive system. Belts are lightweight and low-friction, making the Reno a speed demon when it comes to tool movement. This is perfect for projects where time is a factor, like churning out a batch of V-Carved wooden signs or light engraving soft metals. It really shines when you add a Laser Module with unmatched speed vs a Leadscrew.

Belts are also generally more affordable, making the Reno a budget-friendly option for getting started with CNC machining.

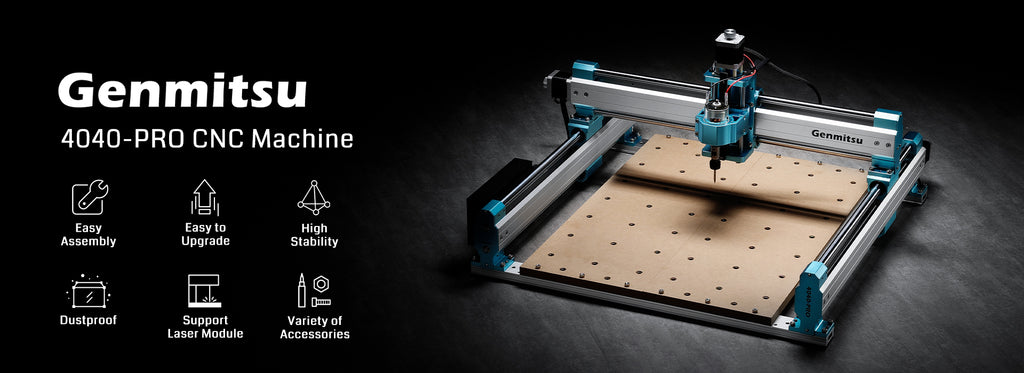

4040 PRO: The Powerhouse

The 4040 PRO takes the crown for accuracy with its lead screw drive system. Lead screws establish a direct connection between the motor and the axis, eliminating the potential for stretching present in belts. This translates to superior control over tool position, making the PRO perfect for projects requiring high precision and intricate details. Imagine meticulously carving a mold - that's the power of the PRO's lead screw drive in action.

4040 PRO MAX: Power and Precision

The newest addition, the 4040 PRO MAX, is the ultimate in stability and accuracy for enthusiasts. It features an upgraded lead screw system and a reinforced frame for even greater precision. Whether you're machining harder materials like aluminum or creating complex designs, the PRO MAX gives you the confidence to tackle more challenging projects. It's ideal for hobbyists who demand the highest level of detail and performance in their work.

Choosing Your 4040

The ideal choice depends on your projects and priorities. Here's a quick guide:

- Choose 4040 Reno for:

- Woodworking (cutting sheets, V-Carve signs,)

- Soft metal engraving

- PCB prototyping (where speed is a factor)

- Cost-conscious applications

- Choose 4040 PRO for:

- Machining complex parts from metal or hard plastics

- Mold making

- Medical device manufacturing (where precision is paramount)

- Applications requiring high cutting forces

- Choose 4040 PRO MAX for:

- Professional-grade metal and plastic machining

- Complex projects requiring top-tier stability and accuracy

- Harder material cutting (e.g., aluminum)

- Serious hobbyist applications with a focus on detail and precision

Remember, there's no single "best" option. By understanding the strengths and limitations of both belt and lead screw drives, you can make an informed decision that optimizes your 4040 CNC for the projects you love to tackle. Happy making!